Pipe Bursting enjoys a resurgence in the light of AMP8

The technology of Pipe bursting was popularised in the late 1970’s and early 1980’s when TRACTO developed a machine, the pneumatic GRUNDOCRACK, at the request of then nationally owned utility British Gas and Severn Trent Water. The objective was to facilitate the installation of replacement water pipes using trenchless methods to minimise disturbance to the surroundings and to save money by working more quickly and efficiently with less disturbance to the customer. The process was further developed to include the hydraulic GRUNDOBURST ladder rod system which can burst pipes from 2” to 32” and install up to 900mm HDPE pipe.

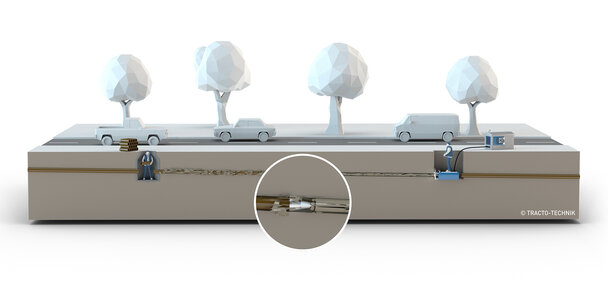

The GRUNDOBURST was designed to break – mainly old, brittle cast iron - pipes underground and pull through new HDPE pipes ready for connection to the water supply. The beauty of the technology was that like for like diameter pipe could be replaced, or if capacity necessitated, a larger pipe could be installed in the same manner and space, dramatically reducing the need to open cut the ground and the associated disruption this causes.

The introduction of AMP8 in April of 2025 and the guidance from Ofwat to prioritise trenchless techniques, has resulted in a resurgence of interest in pipe bursting and subsequently an increase in sales of TRACTO’s purpose-designed GRUNDOBURST.

AMP8 recognises the public frustration of the disruptions caused from perpetual civil engineering works and has prioritised the use of trenchless techniques during the next 5 years of the funding cycle from 2025 to 2031; mandating contractors to use pipe bursting on mains replacement projects wherever possible.

Requiring minimal surface excavations – just two small pits from which to launch the burster – new pipe can be pulled back through the underground hole left by the displaced former pipe by the bursting process. It is not only quicker, but more environmentally friendly. A reduction in spoil waste, noise and dust pollution combined with quicker reinstatement ensures impact on businesses and residents, road closures and traffic disruption are minimised as much as possible.

The TRACTO GRUNDOBURST is a purpose-designed machine that offers the ultimate flexibility in pipe bursting. There are 6 models in the range from the 400G to the 2500G offering 40 to 250 ton pulls and the ability to install pipe sizes up to 900m. The specialised range of accessories and bursting tooling available only from TRACTO ensure each job can be completed with ease.

The GRUNDOBURST offers a unique ladder rod system of hooking rods together which allows some lateral flexibility enabling pipes to be installed, even on a slight curve. The ladder rod and hook mechanism removes the need to screw the rods together, which is not only quicker, but also removes many of the manual handling elements. Another in-built innovation is the red safety guard that prevents anybody standing directly behind the machine in the burst rod exit area.